Success or failure of a hearing instrument fitting is often pre-determined by the selection of the impression-taking technique and material employed. Ear impressions taken with: 1) a higher viscosity (firmer) silicone; 2) the patient’s mouth wide open; and 3) the impression showing the ear canal second bend appear to be the most suitable for manufacturing properly fitting earmolds and hearing aid shells. This study found that predictions of individual ear canal qualities like softness or movement through direct observation were, in general, too inaccurate to use reliably.

For years, earmold labs have been unable to agree on which techniques and materials result in the best impressions: some labs recommend soft low-viscosity silicones, some prefer medium viscosity, while others advise the use of a firmer higher-viscosity silicone. Recommendations relative to mandibular movements also vary. Certain labs insist on having the patient chew, while others prefer an impression taken of when the patient’s mouth is relaxed or open. A number of labs claim that the techniques and materials are irrelevant.

There are no industry standards for impression-taking because there have been no definitive studies looking at the various recommendations. Thus, the hearing care field continues to operate under confusing— and often contradictory—advice.

This inconsistency of advice should be of concern to dispensing professionals; keeping track of who-wants-what relative to the various labs is a challenge for offices that order hearing instruments from numerous sources. With all this contradictory advice, they wonder, “Does it really matter how the impression is taken? If it does, who is right? What will result in the best fit for my patient?”

Audiologists enrolled in the distance education AuD degree program at PCO School of Audiology conducted a series of studies to clarify this issue.1

Research

In the first study, the audiologists evaluated impressions taken with different techniques and materials. The canal area on each ear impression was measured in the anterior-posterior plane, between the ear canals first and second bend, where the seal area in hearing instrument fitting occurs.2

Figure 1. Ear canal stretching with the syringing of a

higher viscosity impression material.

Experienced dispensing professionals know that not all ears are alike; the softness of ear cartilage and the extent to which the canal is affected by jaw actions can vary considerably between clients. The curve in Figure 1 shows the differences for over 300 ears relative to the measurements taken from impressions made with a lower (softer) viscosity and a higher (thicker) viscosity silicone from the same ear. The majority of the ears appeared to be firm and unwilling to stretch. About 80% of the ears, marked as “Area A,” stretched at the seal area less than 0.5 mm with the syringing of a higher viscosity silicone. The softer ears expanded more, with some ears showing stretching well over a millimeter.

What does this mean for hearing aid fittings? Whatever silicone (light or viscous) is used for firm ears, the impression will be satisfactory to manufacture a properly fitting earmold or hearing aid shell.

Figure 2. Ear canal widening with jaw actions.

The curve in Figure 2 presents the increase in the ear canal diameter measured between the closed jaw and open jaw impression taken from the same ear, for 314 ears. As before, the measurements were taken at the seal area. Close to 75% of the ears, marked as “Area A,” stretched slightly with jaw actions. This means that regardless of the jaw position during impression taking, the majority of otoplastics manufactured for the general patient population will fit fine.

The possibility that the remaining 20%-25% of hearing instruments made from impressions marked as “Area B” in Figures 1 and 2 will fit poorly in the patient’s ear is real. In fact, the data show that 1-in-5 custom hearing aids is returned to the manufacturer for shell rework, and this is a major concern to the labs (Pirzanski, unpublished data).

Because the labs rarely know which impression technique and viscosity were used to take the ear imprints they receive, they developed a variety of strategies to minimize the chance of manufacturing an ill-fitting otoplastic. One of the strategies is to balance the rate of otoplastic remakes with the thickness of wax used to coat impressions. If a lab receives too many complaints of loose fittings and feedback, it will increase wax thickness. If complaints of tightness and discomfort prevail, a thinner waxing will be employed. Over time, this approach seems to produce satisfactory results. However, some patients will be the exceptions in this one-solution-fits-all approach; their instruments will not fit and will require a remake.

A second strategy commonly employed by labs is to “factor” the impression and apply a thicker or thinner wax coating depending on the factor. In this approach, higher gain aids get a thicker coating. There is no evidence that one of these two strategies works better than the other. Frankly, most of it relies on hunches and guesswork!

Considering this, some field consultants maintain that, if dispensing professionals provided more information regarding the formation of the patient’s ear—such as the softness of the ear cartilage and the extent to which the canal is affected by jaw actions—the wax thickness could be customized and the number of successful fittings increased.

To verify if providing such information would be of any assistance, the audiologists in this study conducted two additional investigations. In the first, they assessed the softness/firmness of the patient’s ear tissue through examining the canal aperture. Next, they took two impressions from the ear using a lower and a higher viscosity silicone. The canal portion on each impression was measured with a caliper. The measurements were taken at the seal area, which is located 5-10 mm from the canal aperture. The collected data were then compared with the predictions (Figure 3).

Figure 3. Predictions of dispensing professionals

regarding ear canal cartilage flexibility via examination

of canal aperture (soft, medium-soft, and firm) for

100 ears. Prediction rates were very poor. This should

not be a great surprise; the cartilage of the pinna is not

physically contiguous with the cartilage of the ear canal.

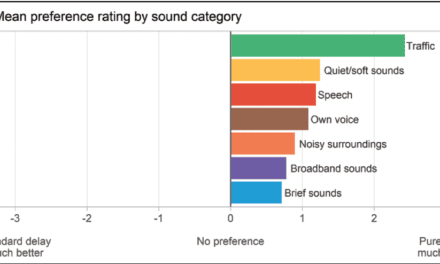

In the final study, the audiologists focused on mandibular movements. With the use of an otoscope, they observed the magnitude of the ear canal wall movements in each subject’s ear while the subject was closing and opening their mouth. To verify the accuracy of their observations, closed jaw and open jaw impressions were then taken and measured. The results are provided in Figure 4.

Figure 4. Predictions of dispensing professionals

regarding ear canal activity (no activity, mild activity,

and severe activity) through video otoscope observations

of 100 ears. As with ear canal cartilage flexibility, the

evidence shows that it is difficult to predict ear canal

activity. In general, the ear canals were less susceptible

to movement than predicted.

For the purpose of these studies, ear canals that stretched less than 8% were classified as “firm”; canals that stretched between 8%-16% were considered “medium-soft”; and canals that stretched more than 16% were classified as “soft.” The 8% value is the equivalent of a 0.5 mm stretching measured on an impression possessing a 6.3 mm wide canal. The 6.3-mm value is the average ear canal diameter measured on 100 impressions by the first author.

Relative to cartilage softness (Figure 3), the predictions proved to be highly inaccurate:

- For 30 ears pre-judged as soft, only two ears (6%) were truly soft at the seal area. Fourteen ears were firm.

- For 52 ears pre-judged as medium-soft, only 5 canals (10%) were medium-soft, and the rest were firm.

- For 28 ears pre-judged as firm, 19 canals (67%) were firm. The higher accuracy established for this group is expected considering that 80 of the 100 ears evaluated in this study were firm.

This study proves that the softness of the cartilage at the canal aperture gives poor indication of the cartilage softness just 5-10 mm deeper into the canal. This finding is consistent with the fact that, anatomically, the cartilage of pinna is physically not contiguous with the cartilage of the ear canal.3 In the majority of subjects, the cartilage deeper in the canal was firmer or much firmer than originally thought.

Figure 4 shows the variations in the ear canal widening as a result of jaw actions:

- For 60 ears classified as not being affected by jaw actions, the observations were correct for 39 (or 60%) of the ears.

- For 32 ears thought to be moderately affected, the observations were accurate only for 6 ears (18%).

- Finally, for 8 ears believed to have a very active ear canal, only one was very active.

This study found that detecting canal wall movements could be a deceptive task and that even significant movement seen in the canal will not necessarily affect the seal area. The ear canals were less susceptible to jaw actions than expected.

To better understand the information presented above, the reader should consider that the curves in Figures 1 and 2 present the data obtained from the same 314 ears. Each curve shows the data sorted from the smallest to the largest value for a given condition. The 100 ears evaluated for cartilage softness and the 100 ears evaluated for jaw actions were not the same ears. Still, all curves in Figures 1-4 exhibit similarities. In any group size, there were individuals possessing ears that stretched/widened significantly more than others.

Conclusions

The findings presented here suggest:

1. Approximately 80% of human ear canals were firm and little affected by jaw actions. Hearing instruments made for these ears would fit successfully regardless of the technique or material used.

2. This ratio of 75-80% “guaranteed” fittings give some labs the false confidence that all impression techniques yield similar results.

3. About 20%-25% of ears widened as a result of employing a more viscous silicone or the open jaw technique. The magnitude of the stretching greatly varied among these ears, raging from 0.5 mm-2.5 mm. These ears would be at risk of poor fittings if ear impressions were not taken properly.

4. The magnitude of the ear canal stretching, either due to the impression technique or material, could not be predicted for the majority of ears. In fact, the extent of the actual ear stretching/widening was often the opposite of the prediction based on impressions evaluation. Despite the audiologists’ best efforts, the predictions were only 25% accurate for the canal softness and 46% for jaw actions. No better than flipping a coin!

The authors recommend that all ear impressions for custom products (except open canal fittings) be taken with a more viscous silicone with the patient’s mouth wide open. The reasoning that supports this opinion is simple: If the ear canal is firm and not affected by mandibular movements, the impression will not differ from an impression taken by any other technique. However, if the canal is soft and/or active, the “open-mouth” impression will most accurately capture the extent of these changes. This will ensure the greatest probability that the otoplastic will result in a proper seal with a secure and comfortable fit. A chart providing the viscosity of commonly used impression materials is available from the authors online.5

It should be stressed, however, that higher-viscosity open-mouth impressions are still subject for skillful processing by the earmold lab technicians. This is due to the fact that such impressions are bigger than impressions taken with other techniques and therefore pose a risk that the resulting hearing instrument can be uncomfortable, commonly at the osseous (bony) portion of the ear canal. To prevent this, ear impressions should be skillfully “detailed” by the earmold lab technician. When these criteria are met, the fittings of the resulting otoplastics are most satisfactory.4

Summary

The data gathered by the audiologists participating in this study indicate that future success or failure of a hearing instrument fitting is often pre-determined by the selection of the impression taking technique and material employed. Ear impressions taken with: 1) a higher viscosity (firmer) silicone; 2) the patient’s mouth wide open, and 3) the impression showing the ear canal second bend appear to be the most suitable for manufacturing properly fitting earmolds and hearing aid shells.

Such impressions eliminate the guesswork in otoplastic manufacturing because they carry all the unique information about the underlying structures of the individual’s ear canal. In-field hearing instrument fittings have confirmed the superiority of this technique.5

|

Correspondence can be addressed to HR or Chester Pirzanski, Starkey Labs Canada, Ltd, 7310 Rapistan Ct, Mississauga, Ontario, L5N 6L8, Canada; email: [email protected].

References

1. Pirzanski C, Berge B. In: Course ACD 602 Earmold Technology. PCO School of Audiology. Available at: www.audonline.org. Accessed Summer 2000-Fall 2002.

2. Pirzanski C. The anatomy of perfect ear impression. Hearing Review. 1998;5(12):20-24.

3. Oliveira R, Hoeker G. Ear Canal Anatomy and Activity. In press.

4. Pirzanski C, Berge B. An ear impression technique that works. Hearing Review. 2002, 9(12):24-27,53.

5. Pirzanski C, Berge B. Ear impressions: Art or science? Available at: www.audiologyonline.com. Accessed: March 7, 2003.