Utilizing eBusiness technology to enhance your workflow.

For the sake of this article, we will define the use of computers and the Internet as operating on an electronic business platform—“eBusiness.” For today’s hearing care professional, virtually every step in the process to fit a patient with hearing instruments now involves computers, and more and more it is also directly involving the Internet—it is all becoming eBusiness.

Think about what you do on a typical day in the office: Dealing with patient records, doing diagnostics, ordering products, fitting and verifying hearing instruments, billing and follow-up, staying up on the latest research, taking a class to obtain your CEUs, returning an e-mail to a patient or colleague—nearly all of these things rely on having computer systems, integrated equipment, and the Internet. Yes, everything we are doing these days is eBusiness.

Where does the hearing instrument manufacturer fit into the hearing care eBusiness picture?

Perhaps the best answer to this question is as a “facilitator.” The remainder of this article will discuss how a manufacturer can provide the necessary tools and systems to allow the hearing care professional to change and enhance workflow in their practice, specifically illustrating how the interaction between the hearing care professional and the manufacturer can be completely changed for ordering hearing instruments and managing account-related functions.

Evolution of One eBusiness System

In 2001, Siemens Hearing Instruments, Piscataway, NJ, was one of the first hearing instrument manufacturers to utilize the Internet as a platform for eBusiness and eCommerce as a means for interaction with our hearing care professional customers.

Saying “we have a Web site” and saying “we have an eBusiness platform” are two very different things. There is a significant difference between simply having a Web site where some information about a company and its products can be found, and having an eBusiness site where true eCommerce transactions can take place. The latter is what empowers hearing care professionals to change how they interact with a manufacturer and can completely alter their workflow—in a positive way—in the process.

Also in 2001, Siemens introduced its first eBusiness platform version known as “Online@SHI.” It provided the industry’s first Web-enabled custom product order form. From that humble beginning, the Siemens eBusiness platform has evolved into what is known today as “mySiemens,” a truly comprehensive eBusiness platform for customers to interact with Siemens for nearly every aspect of our business (see Figure 1).

As mySiemens developed over the last few years, Siemens Hearing Instruments has had to change almost everything it does in terms of internal business systems and manufacturing systems. The entire approach to doing business with a hearing care professional has changed dramatically—even the corporate “culture” at Siemens has had to evolve and adapt to a new way of thinking and doing business.

Virtual Integration

Before we look more specifically at these Siemens-provided eBusiness tools, it is worth discussing and gaining a basic understanding of the concept of “virtual integration,” because that, in essence, is what eBusiness is all about.

The entire delivery chain for a hearing instrument—from the initial order through delivery and fitting to the patient—was once a number of discrete steps, some performed at the hearing care professional’s office and some at the manufacturer.

But now, the entire process has been electronically integrated in a way that empowers both the hearing care professional and the hearing instrument manufacturer to work within an improved workflow.

Framing the idea of maximizing efficiency in eBusiness terms, vertical integration—the well-known concept of when a business takes ownership of all aspects of the delivery channel to maximize efficiency—becomes virtual integration. Both the manufacturer and hearing care professional achieve gains in efficiency because both are working on a shared platform, accessing the exact same data, and avoiding obstacles like double entry of data and the need to be tied to a schedule based on “regular” business hours.

This shared platform includes information not only for ordering hearing instruments, but also for all other aspects of managing the business between these two entities. Essentially, all aspects of the business being done between the manufacturer and the hearing care professional are now integrated in the virtual world that is facilitated by the Internet and the supporting eBusiness structures put in place.

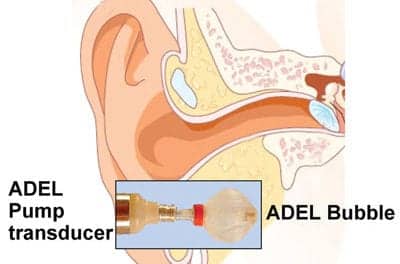

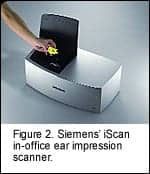

In the last year, Siemens rolled out the iScan™ in-office impression scanning device (see Figure 2). iScan is one key aspect for making the concept of “virtual integration” a reality to the hearing instrument dispensing business, because now it is possible to order a hearing instrument completely electronically without ever sending an ear impression to the manufacturer.

The introduction of iScan demanded the development of a complete electronic information exchange between the hearing care professional and manufacturer. It also required that Siemens (or any manufacturer utilizing data from iScan) have systems in place enabling the manufacture of custom hearing instruments (or BTE earmolds) to take place without having the physical ear impression at the factory. This is a radical change in the process, because without a physical impression to work with, completely new processes had to be developed to build the hearing instrument shell and, perhaps more important, to verify the quality of the fit.

iScan is a desktop scanning device, which is connected to a PC via the USB port. It utilizes an optical scanning and image processing technology called Color-Coded Triangulation (see Figure 3). The ear impression is placed in the iScan chamber, and the scan process is started by the user. In a process taking approximately 3 minutes, a series of images of the impression are obtained and software algorithms are used to “knit” all these images together to form the final 3-D image. The user then has the ability to rotate and view the impression, and add any annotations to it, for example, directions highlighting an area of the scan that they want noted by the manufacturer (see Figure 4). In addition, the user can indicate the horizontal plane for instruments utilizing dual microphones and also indicate where to cut the canal, and even specify details for the angle of the cut, if so desired (see Figure 3).

Processing the Order with the Manufacturer

After the scan is completed, it can be attached to an eOrder via the mySiemens electronic order form. Using mySiemens, the eOrdering process is very easy. After logging into the password-protected mySiemens site, the hearing care professional can access the eForm for custom products, complete the 100% validated order form, attach the scan file, and submit the order to Siemens. The process is straightforward and very simple. Time studies have indicated that utilizing this electronic process and following the workflow suggested by Siemens, the process takes no longer than filling out a paper order form. However, due to its validation feature, the order is being processed much more accurately with a much higher probability of getting through the system without any reason for Siemens to contact the hearing care professional about the order.

eOrdering Made Highly Accurate by “Validation”

The term “order validation” means that once the hearing care professional has selected the model and amplifier type, only valid option choices for that model and amplifier type are presented as they move forward to complete the order form. With the plethora of choices that are available on today’s high-end custom products, the user does not have to remember what can and cannot be ordered for a particular model. Each of the choices will be “checked” by the system to ensure that once the order is in house, it can flow through manufacturing smoothly and efficiently.

The goal of validation is to avoid a “kick-out,” meaning any reason that causes the order to be returned to customer service for contact with the hearing care professional to clarify the desired options. Kick-outs are the bane of good turnaround time—they delay the delivery of the instrument back to the patient.

At Siemens, the use of electronic ordering with validation has reduced the kick-out rate on a long-term basis from approximately 12% to 2%. That translates to 80% fewer calls from Siemens back to the hearing care professional for reasons related to order clarification. This savings of time and effort, for both the manufacturer and the professional, means overall faster turnaround time of the order.

While the above description was based on the mySiemens eForm, Siemens also offers the same concept via the NOAH eTONA-based eForm that is available to users of NOAH 3.5.2 or above.

A different approach to manufacturing

Once an office is set up with iScan, there is a major change in the manufacturing process for those hearing instruments ordered via iScan. Remember, there is no longer a physical ear impression being sent to the manufacturer, only an electronic image. The days of technicians working hands-on to “detail” a physical impression are over. Everything now happens in the virtual world—from image detailing that prepares it to become the shell type desired and the placement of all the electronics, to the quality control for the final fit, essentially everything happens inside the computer. This has meant great changes in the manufacturing process at Siemens, including retraining technicians who are used to working with and holding a physical impression in their hand, to work completely in a virtual world.

Working this way has also opened new insights into shell fit. Before, when working with a physical impression, the cast created to check the potential fit in the ear provided a somewhat limited ability to see the detail in the area where there might be a fit problem. Now, using a virtual cast as the viewer, shell fabricators and QC personnel can get a much more detailed view, including overlaying images and zooming in and out of problem fit areas to see more precisely what needs to be changed to get the best possible fit.

So, it is clear that using in-office scanning and eOrdering has made a great impact on how hearing care professionals place orders, how much control over the orders they have, and, at the same time, how the manufacturer now processes an order and builds custom hearing instruments.

Around-the-Clock Monitoring

Using the eBusiness platform allows Siemens and the hearing care professional to work on a system where everyone truly has access to the same data at any point in the process. Now, it is possible for the hearing care professional to track any order placed with Siemens 24 hours a day, 7 days a week, and know where an order is in the manufacturing process. And when the finished hearing instrument is completed, the shipping information (tracking number) also becomes available.

Far Beyond the Order Process

Although ordering products is certainly one of the main things you do with a hearing instrument manufacturer, utilizing an eBusiness platform goes far beyond that when it comes to interacting with a manufacturer.

Utilizing an eBusiness platform is a way to recapture time. You no longer have to make a phone call to your sales or customer service representative and risk being on hold, or simply feel the pressure to call during “regular” business hours. The mySiemens eBusiness platform is open 24 hours a day, 7 days a week, 365 days a year. Although no one is suggesting anyone work all those hours, it is a matter of utilizing this eBusiness technology to empower you to work and be productive when it fits your schedule. Maybe you like to come in early, or stay late, or work from home in the evening or even on a weekend?

A comprehensive eBusiness platform like mySiemens allows you to do much more than order products, it also allows you to (see Figure 5):

• Work with all aspects of your account including viewing and printing invoices and statements and making online payments to your account

• Place repair orders using the eRepair form

• Look up serial number and warranty

• Download software updates

• Order batteries, impression material, and other hearing instrument accessories

• View and/or download datasheets or other technical material sheets

• View and order standard marketing materials

• Design your own custom version of marketing materials, and send them directly to Siemens or another vendor for printing and mailing

• Review continuing education offerings and register for courses or Webinars

• Check special promotional offers

As a technological innovation in our industry, utilizing all the aspects of the eBusiness platform is having a great impact on the way hearing care professionals interact with Siemens, and that impact on the business is growing.

As of mid 2006, Siemens now has hundreds of iScan systems in use at customer sites. Also at this time, more than 50% of Siemens total volume of custom product orders now arrive electronically. These two facts alone illustrate how business has been impacted by this eBusiness platform and its capabilities. In addition, this technology has had significant impact on kick-out rates (lowering them by 80%), and therefore is having a direct impact on turnaround time for the custom hearing instrument fitting cycle. It is foreseen that further development of this technology and increasing use will only continue to have further positive impact on our industry.

And overall this technology is getting high ratings from its users. In a recent survey of Siemens eBusiness platform users, 97% indicated that they were satisfied or very satisfied with the iScan eOrdering system and would recommend its use to another professional colleague.

eBusiness platforms are the future in the hearing care industry in terms of the way hearing professionals interact both with their chosen manufacturers and, potentially, even more with their patients.

William Lesiecki, MA, is the director of product marketing in the Software and E-Solutions department of Siemens Hearing Instruments Inc, Piscataway, NJ.