A dedication to the development of superior hearing-aid technology has propelled Salt Lake City-based Sonic Innovations into the world marketplace.

Coming off another year of remarkable growth, Salt Lake City-based Sonic Innovations Inc is closer than ever to achieving its goal of becoming a leader in the hearing-aid industry. Already, the company—just shy of a full decade old—claims title as the field’s seventh-biggest player.

Sonic Innovations’ business strategy targets the estimated 3 million Americans who have bought a hearing aid but are dissatisfied with the performance of the product, plus the roughly 24 million others who could benefit from a hearing aid but have yet to buy one.

“Users of hearing aids typically complain that the devices offer poor sound quality and are too visible, uncomfortable, unreliable, and expensive,” says Gregory N. Koskowich, PhD, vice president of research and development. “We’re tapping into that discontent, and growing as a result. There are more and more hearing-impaired adults who want to continue enjoying an active lifestyle. Such individuals are often quite eager to obtain the best that technology offers so they can. That’s why more and more of them are using our products.”

Without question, Sonic Innovations possesses a significant competitive edge in the form of novel applications of the technology undergirding its hearing aids.

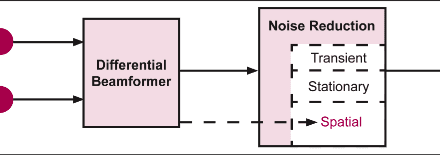

“Our products use digital signal processing [DSP], as do a number of other hearing-aid companies, but what makes our approach truly different is that we have embedded onto the DSP platform unique and very sophisticated multichannel compression algorithms derived from mathematical models of human hearing,” says Victor Bray, PhD, vice president of auditory research. “These algorithms compensate for cochlear hearing loss. We feel that this technological approach is helping us set a new standard for consumer satisfaction because it delivers a more natural sound quality than was possible with previously available hearing aids.”

User Tailored

In addition to cutting-edge performance capabilities, Sonic Innovations’ products are standouts because they rely on the smallest, single-chip DSP platform ever installed in a hearing aid, according to company officials.

“Our hearing aids are tiny,” says Bray. “Our newest hearing aid, in fact, is extraordinarily small and represents a feat of mechanical engineering as well as a feat of electrical engineering for that particular chip design.

“Not many companies, when they introduce a new hearing aid with a new signal processor, launch in the completely-in-canal format. They typically launch in the behind-the-ear format and then work down to the smaller sizes. We, in contrast, launched with completely-in-canal and worked our way up.”

Since the company’s founding in 1993, Sonic Innovations has introduced multiple lines of DSP-based hearing aids, all of them oriented toward addressing sensory neural hearing loss.

The first to roll out was Naturatm in late 1998. This was followed 18 months later by Conformatm, and then Conforma 2 SEtm. Also in 2000, the company released Natura 2 SEtm, which the company claims is clinically proven to improve a user’s understanding of speech against background noise. Approximately 6 months after that came Altairtm. The company now is rounding out its lines with Adessotm and Tributetm.

“Our Natura 2 SE products contain a noise-reduction feature and an optional directional microphone to suppress background noise,” says Merritt Johns, marketing manager. “The Altair line includes the directionality option and provides high-quality, digital sound processing at a price equivalent to that of low-end digital hearing aids. The new Tribute line offers the same digital sound processing at a programmable analog price-point.”

Adesso is the company’s second-generation instant-fit product. It contains a small core that houses the hearing-aid components and a disposable soft shell that fits snug over the core. Like Natura 2 SE, this product line offers noise reduction. Being instant-fit, audiologists and hearing-aid specialists can send a patient home with the hearing aid on the same day they are tested and evaluated, Johns indicates.

“That’s obviously advantageous for everybody from the clinical perspective, but it’s also beneficial from the business side,” she says. “It provides a solution that helps with the way clinicians do business. First, it eliminates the usual minimum 2 weeks of waiting before the patient can receive a custom-fit instrument. Second, if a patient’s hearing aid needs repairs, clinicians now have a way to avoid the problems of the patient going for days or weeks without a hearing aid while the custom-fit product is being repaired.”

All of Sonic Innovations’ products are tailored to the individual user’s hearing requirements, Koskowich indicates.

“Each channel is individually adjusted to make sure that, for every user, sounds within each half-octave frequency range are heard clearly and in the right contrast to sounds in every other channel,” he says. “This is the equivalent of adding the custom control of a graphic equalizer to the hearing aid, which before had only the limited control that is comparable to stereo bass and treble adjustments, or even simply volume adjustment.

“The adjustments are made using either a handheld, laptop, or desktop computer. Through a graphical software package we provide, the hearing care professional controls each frequency channel simply by sliding icons up and down. The programming system plays a tone in each half-octave band, which enables the professional to test different sound levels in each channel until proper settings are determined across the full range of frequencies. The end result is a highly personalized hearing aid that delivers a more natural sounding experience.”

Because of the customization requirements, Sonic Innovations products are sold to users through clinicians only, Koskowich notes. And, sales are generated mainly by word-of-mouth advertising from clinician to clinician, but direct company-to-clinician marketing also plays a key role.

“We have in place a very potent sales force consisting of highly trained professionals who know what it takes to get product out to audiologist practices and to hearing-aid specialists,” says Koskowich.

Moreover, the company provides an extensive training program to help clinicians become intimately familiar with the technology. A team of trainers travel around the nation and give lectures and participate in seminars on the company’s behalf. Additionally, Sonic Innovations employs a corps of field instructors whose mission is to provide quick-response training services to clients.

In addition to trainers, Sonic Innovations also operates a customer-service department, staffed by audiologists and technical-support experts so that help is always just a phone call away, says Johns.

Laying a Foundation

Beyond its United States operations, Sonic Innovations is building a thriving international business, which it supports from offices in Denmark and Australia. Its worldwide manufacturing facilities, however, are located domestically, in Eagan, Minn. Counting all locations, Sonic Innovations currently employs more than 450 individuals.

Compare that to when the company was started. Back then, it consisted of just a handful of engineers, led by digital sound pioneers Douglas Chabries, PhD, Thomas Stockham, Jr, PhD, and Carver Mead, PhD.

A formidable team those three were—and still are (although less active with the company today, they continue on in the capacity of advisors). Chabries, now dean of the College of Engineering and Technology at Brigham Young University, was, even before joining Sonic Innovations, an internationally recognized authority on digital speech processing. He formerly headed a Navy laboratory involved in the research and development of underwater acoustic signal processing technologies, and is the holder of 10 patents in the areas of adaptive signal processing and digital hearing enhancements.

Stockham, meanwhile, is regarded by many as the “father of digital recording.” In 1976, he made the world’s first digital recording, and his subsequent work in the field of digital music recording and editing led to the development of compact disks and CD players, for which he was honored with an Emmy award from the Academy of Television Arts and Sciences and a Grammy award from the National Academy of Recording Arts and Sciences.

Then there is Mead, who helped achieve the miniaturization of Sonic Innovations’ technology. Mead currently is the California Institute of Technology’s Gordon and Betty Moore Professor of Computer Science, and was a trailblazer in the development of very large scale integrated circuit technology. In 1990, he won the Institute of Electrical and Electronic Engineers Signal Processing Society award for best paper presented, “An Analog Electronic Cochlea.”

After the company opened its doors for business, “we spent the next 3 years working to transform the technology into a product,” says Koskowich. “The focus at the time was on sound quality. We were trying to deliver a benefit where others hadn’t in the past.”

In 1996, Andrew Raguskus joined the company as president and chief executive officer, having completed service as chief operating officer at a California-based computer company and, before that, as a senior vice-president at a sound systems manufacturing concern.

The hiring of Raguskus was a significant milestone for Sonic Innovations. It was seen as a first step in building a management team that could help the company achieve its market ambitions. Under Raguskus’s leadership, Sonic Innovations attracted more than $31 million in venture capital investments prior to going public in 2000.

“We went from being a company with zero revenues 3 years ago to one with annual net sales of $57 million in 2001,” says Koskowich. “Currently, we’ve attained a global market share of 3%—or 9% when you look specifically at digital.”

Not Standing Idly By

And the company continues to grow. In February alone, for instance, Sonic Innovations announced that it had acquired OMNI-ReSound ApS, a Denmark-based distributor of hearing aids and tinnitus products that primarily sells to Danish public sector dispensing clinics and hearing health care centers (which currently account for approximately 90% of that country’s sales of hearing health care products, according to Sonic Innovations officials).

However, other hearing-aid producers ranked higher in terms of market share will not sit idly by and allow Sonic Innovations to climb over them. They will fight back—or at least seek to—by introducing what they hope will be innovative DSP-based products of their own, and offer them at lower price-points.

How will Sonic Innovations counter that? According to Koskowich, it will entail staying focused on the things that have worked for the company thus far.

Here again is Bray: “We believe that the wisest course is to continue developing the best products possible with the greatest benefit possible to the hearing-impaired and so allow our products to continue building their reputation and achieving higher and higher levels of brand loyalty.

“We have a lot more innovation in the development pipeline; innovations based on fresh ideas from our technology pioneers—Drs Mead, Stockham, and Chabries. I can’t reveal what those ideas are, other than to say they’re exciting. What I can reveal is that, as far as innovation goes, we’re really only just getting started.”

Rich Smith is a contributing writer for Hearing Products Report.