A review of what we can now offer patients relative to customization

Custom in-the-ear products have come such a long way in the past 5 to 10 years that it’s worth reviewing some of these changes and the potential benefits they provide to consumers.

Building long-term customer value is a common goal across nearly every customer-facing industry. Whether you are a hearing care professional operating independently, are part of a health care institution, or play a role in manufacturing, the hearing industry is built on developing relationships and bringing a better quality of life to hearing aid wearers for the long haul.

Eric Branda, AuD, is senior manager of product management at Siemens Hearing Instruments, Piscataway, NJ.

These relationships are often formed when we build value through personalized service.1 In the traditional sense, service refers to the assistance (services) you offer your customers. But personalized service—especially in the hearing aid industry—is closely tied to product. The ability to tailor a product to what a specific customer needs helps build lasting customer loyalty. And perhaps no hearing product achieves this better than the custom hearing instrument.

While there is no arguing that all hearing instruments are in some way customized, custom hearing instruments are exceptional because they provide a personalized, individual experience—one that can make the wearer feel both empowered and unique. These feelings often stem from the knowledge that custom hearing aids are custom-made. Just like two ears, no two custom instruments are the same—and wearers find satisfaction in knowing that their custom instruments are made for their ears only.

Despite all this, recent industry trends point to a clear market decline in custom in-the-ear (ITE) hearing instruments.2 This decrease can be attributed to the increasing popularity among receiver-in-canal (RIC) and behind-the-ear (BTE) style hearing instruments during the past decade.

There is a high level of customer satisfaction found within the same-day service RIC and many BTE devices deliver. A patient can receive a hearing evaluation, hear the recommendation, and be fitted with a state-of-the-art pair of BTE hearing aids within a single afternoon. In the consumer world, there is significant buying power with same-day delivery and instant satisfaction.

Smaller = Better: Tinier Instruments Made Possible by Advanced Imaging

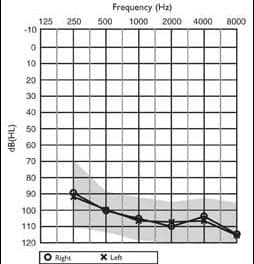

Figure 1. Through 3D modeling software, hearing aid shell designers can use their experience to identify and note areas that may prove problematic for the patient in terms of comfort or retention.

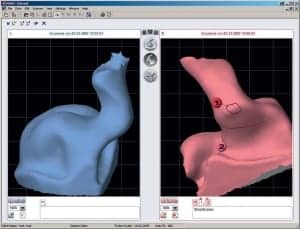

Recent advances in the manufacturing and assembly techniques behind custom hearing instruments have enabled tiny—even invisible—hearing solutions with greater flexibility and a higher probability of a guaranteed fit. Using the latest 3D modeling software, hearing aid manufacturers use feature recognition technology (Figures 1 and 2) to better manipulate digital ear impressions, identifying key anatomical points of the ear and precisely modeling the hearing instrument accordingly. The result is a precision-built custom hearing instrument that provides a comfortable fit in the smallest possible size. After all, in an industry where discretion is highly valued (particularly by first-time users), smaller is almost always better.3 In addition to the advancements in software, progress in the physical manufacturing process of hearing instruments has resulted in a smaller hearing solution made possible by more flexible designs, solid state circuitry, and floating components.

More Flexible Designs

Smaller components reduce the size of the hearing instrument. This allows for the largest vent possible. A larger vent is particularly helpful for those patients with little-to-no hearing loss in the low frequencies and can provide for more natural sound quality and reduced occlusion effect.

Thus, building smaller custom instruments has the added benefit of appealing to wearers with wider ranges of hearing loss and those who value sound quality and comfort as much as discretion.

Solid-State Circuitry and Telecoil Functionality

Solid-state circuitry allows for seamless and instantaneous telecoil operation at all performance levels. Consumer demands and expectations for telecoil performance and a recent resurgence in public awareness of telecoils create a need for more consistency and better usability—regardless of whether the telecoil functions automatically or is selected by the wearer.

Floating Components

Figure 2. Once the ear canal is scanned into the 3D modeling software, technicians can look at various options for discreet placement of the hearing aid, as well as use the software to make the device as discreet as possible.

Components no longer need to be fixed to a faceplate in predetermined locations. In the past, this resulted in a larger instrument to accommodate this fixed spacing. Particular circuitry elements are considered “floating” and can be wrapped in silicone and affixed where they best suit the hearing instrument, allowing for optimal positioning and the smallest possible device.

Smaller, more discreet instruments are not the only result of these advances in manufacturing and assembly. By making more efficient use of the instrument’s real estate, manufacturers can now produce innovations like wireless completely-in-the-canal (CIC) instruments. So customers who want a CIC, yet still want the advantages of Bluetooth wireless technology, no longer have to choose one or the other.

Wait No Longer

In addition to size, there is also a concern for custom instruments’ turnaround time. We live in a culture of immediate gratification and a sort of “fix-it-now” mentality. After putting off their hearing evaluation an average of nearly 7 years,4 the last thing first-time wearers want to do is wait weeks for their new hearing aids to be delivered. They want the answers now and the solution faster—and who can blame them? This is why some professionals recommend a BTE solution that allows the patient to walk out that first day with their purchase in hand.

However, the days of impatiently waiting for a custom hearing instrument are long gone. The most up-to-date, optimized ear impression scanning technology, along with manufacturing process improvements, allow a custom hearing instrument to be ready to fit within as little as 2 to 3 days after being received by the manufacturer—without requesting special rush services.

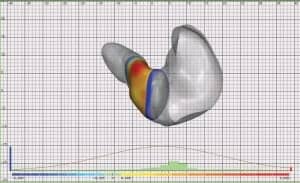

Figure 3. Impressions can now be scanned and sent to any manufacturer within a matter of minutes—eliminating several days of waiting for the custom product by the consumer and dispenser.

With the appropriate scanning software, an earmold impression can be scanned and submitted electronically to any manufacturer or earmold laboratory in less than 2 minutes (Figure 3). This greatly reduces processing time and enforces multiple checkpoints for order accuracy, thus streamlining the ordering process into a simple, fast online method. Additionally, because impressions are now electronically stored, it’s easy to retrieve the impression file when needed rather than taking a new impression. Both save time and money.

Not only does this innovative method deliver products more quickly to the patient, there are other advantages for the hearing care provider too. With electronic delivery, there is a savings on paper, shipping costs, staff time, and office materials. With the superb accuracy of recent scanning software—up to 1/10 of a millimeter—hearing care professionals can ensure a better fit of the custom mold. In the end, the hearing care provider can guarantee a quality, more efficient and personalized service and solution. It’s a win-win scenario.

Drivers for Custom Hearing Instruments

As Baby Boomers begin streaming into hearing care offices across the nation, professionals should understand not only the technological advancements and possibilities with custom hearing instruments, but also what these potential wearers want and what fuels their desire for custom instruments.

Doing so helps hearing care professionals connect with and provide the individualized care and services that are essential to building long-term relationships. Three important drivers behind custom hearing instruments are discretion, comfort, and ease of handling.

Discretion. The major motivation for custom hearing instruments is size.3 Unfortunately, hearing aids are not fashionable by our cultural standards. Many wearers are embarrassed by their hearing loss and would prefer zero physical evidence of such.

Custom ITE instruments provide powerful, discreet, aesthetically pleasing hearing solutions. Some instruments can even claim invisibility and are completely and entirely invisible to the naked eye when worn (Figure 4a). For wearers who may not be good candidates for invisible instruments, nearly invisible customs offer almost the same discretion. Such instruments make an excellent alternative and are only slightly larger than their invisible counterparts (Figure 4b).

Figure 4a-c. Left: CIC shell with a large custom vent. Middle: Nearly invisible custom hearing aid. Right: Deep-canal fitting custom aid with dome.5

Comfort. A truly customized hearing instrument becomes a part of the patient’s being and allows for a perfect, comfortable fit. A patient searching for a higher level of comfort and versatility may gravitate toward a custom hearing aid, as it offers a smooth, secure, and ideal fit with freedom to wear other personal accessories at the ear level, such as sunglasses, bike helmets, and hats. The latest CICs feature virtually no occlusion effect and comfort is maintained via a simple, yet effective, soft dome (Figure 4c).5

Ease of handling. Many hearing aid wearers often experience increasing dexterity difficulties as they age.6 It can be challenging for them to handle a BTE device with two hands and coordinate that effort to ensure a secure placement over and then into the ear. Custom instruments provide a simple solution, with few external buttons and easy one-hand management.

With custom hearing instruments, there is the opportunity to create value through individually tailored solutions—using both technology and a customized fit. It has never been easier to provide patients with innovative technology in the right size and performance level to fit their hearing loss and personal style.

…Or Standing Out from the Crowd

Figure 5. Not everyone wants a discreet solution. Custom ITEs also provide wearers with a range of cool cosmetic options that are visible and appealing.

While discretion ranks among the main drivers for custom hearing, there is still a population of wearers who choose to express themselves through their custom instruments. Wearers who don’t want to blend in can choose bright, colorful shades that match their personal style. New glow-in-the-dark custom hearing instruments are both fun and practical. They’re great for wearers who have trouble finding their instruments in the dark—especially during an emergency (Figure 5).

Summary

Clearly, hearing care professionals can now offer a broad selection of custom in-the-ear hearing instruments alongside innovative BTEs and RICs. Giving hearing aid wearers an experience personalized for their wants and needs shows them that hearing care professionals understand them. And that’s the foundation of building a long-term customer relationship. Manufacturers are sure to maintain their focus on developing diverse product portfolios to suit a diverse—and changing—user demography.

With the latest developments in custom instruments, the hearing care industry is recognizing the ongoing need for and benefits of custom hearing instruments. It should come as no surprise to hearing care professionals that customs are making a comeback. Hearing care professionals can confidently offer more powerful hearing instruments to a greater number of people in less time.

Now, that’s customer value.

References

- Ball D, Coelho P, Vilares M. Service personalization and loyalty. J Services Marketing. 2006:20(6):391-403.

- Hearing Industries Association (HIA). HIA Quarterly Statistics Report, 4th Quarter 2011 Statistics. HIA: Washington, DC; 2012.

- Kochkin S. MarkeTrak VIII: The key influencing factors in hearing aid purchase intent. Hearing Review. 2012;19(3):12-25.

- Kochkin S. MarkeTrak VIII: 25-year trends in the hearing health market. Hearing Review. 2009;16(11):12-31.

- Branda E. Deep canal fittings: advantages, challenges, and a new approach. Hearing Review. 2012;19(4):24-27.

- Parikh P, Cole K. Handling objects in old age: forces and moments acting on the object. J Applied Physiol. 2012;112(7):1095-1104.

Citation for this article:

Branda E. Advances in Customization: Giving Consumers Exactly What They Want, 2012 Hearing Review. 2012;19(06):26-31.