|

| Elliott H. Berger, MS |

When a hearing conservationist wishes to select or assign a hearing protection device (HPD) for an employee, the data they have historically had available are based on optimized fitting scenarios in a controlled laboratory environment that bears little resemblance to the conditions under which workers wear HPDs on a daily basis. There are a number of problems with this approach that are summarized in the following article along with a proposed solution—namely field-fit testing using a technology called field microphone-in-real-ear (F-MIRE).

Problems Associated with NRRs

What is the best way to select or assign a hearing protection device (HPD) to individuals, taking into account their noise exposure, the amount of protection required, and potentially their hearing sensitivity? Today, hearing conservationists attempt to do this using labeled Noise Reduction Ratings (NRRs) that are provided by manufacturers in accordance with the Environmental Protection Agency’s (EPA) hearing protector labeling regulation.

Although this might seem a reasonable approach, it is fraught with error. The largest source of error is reliance on the EPA-required labeled values. These numbers are based upon an optimized fitting scenario in a controlled laboratory environment that bears little resemblance to the conditions under which workers wear HPDs on a daily basis, in what is often referred to as the “real world.”1

The other key problem with the laboratory measurements, as commonly utilized, is that averaged (mean) values for a group of 10 subjects are used to predict the performance for an individual wearer in an occupational setting. Even if the laboratory data were representative of the actual group using the device, the individual variability is large enough that attempts at predicting one person’s performance from group data can easily err by up to 20 dB.2

The answer to both of these problems is individual fit testing. This technology has been available in the laboratory in many forms for nearly 30 years. In fact, the author began publishing research related to this area in 1984.3-6 Only recently has the hearing conservation community started to look more closely at this issue, and there are now a number of potential systems that provide solutions. Aearo, through its E•A•RCALSM laboratory, was able to assess the various fit-testing methods and select what we believe to be the best one.

Methods of Individual Fit Testing & F-MIRE

Historically, the method of fit testing that has garnered the greatest attention is to replicate as closely as possible the laboratory test procedure. In the lab, we ask listeners to track their hearing threshold levels (the quietest sounds they can hear) much like when they take a conventional audiogram to measure their hearing sensitivity. However, we present the sounds from loudspeakers in a test chamber and then repeat the procedure, both with and without HPDs. The difference in the two thresholds is the noise reduction of the device. This procedure is called real-ear attenuation at threshold (REAT), because the attenuation of the HPD is computed from differences in the threshold of hearing, with and without the hearing protector in place.7

To take REAT into the field, we replace the loudspeaker presentation with a headphone presentation (ie, speakers in large circumaural cups), and in so doing limit ourselves to being only able to measure earplugs. However, earplugs are the type of HPD that is most variable in fit and therefore most in need of fit testing.

A principal disadvantage of field REAT testing is its time-consuming nature; each frequency tested takes at least 30 seconds, a minimum of at least one minute to test the fit in each ear, and much longer if multiple frequencies are to be tested. Furthermore, there is inherent variability because the data rely on the listener’s ability to track his/her own threshold, and that process itself has a substantial imprecision of approximately +5 dB for typical employees. Finally, accurate REAT measurements require low background noise so that the open-ear thresholds are not masked and contaminated. Even though field REAT is conducted under large noise-excluding earmuff cups, care must still be exercised to be sure that the environment in which the tests are conducted is adequately quiet.

An alternative approach is to make objective measurements with microphones, what is termed a microphone-in-real-ear (MIRE) technique.4 When applied in occupational settings, this becomes a field-MIRE (F-MIRE) methodology.8 With F-MIRE, we simultaneously record the sound pressure levels in the ear canal under the hearing protector, as well as those outside the HPD. The difference is termed the noise reduction (NR). With suitable correction factors to account for known and measurable acoustic differences between the F-MIRE and REAT, the NR values can be used to estimate the hearing protector’s attenuation.

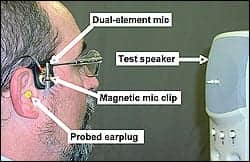

Aearo’s F-MIRE technology incorporates a single small dual-element microphone and associated proprietary technology.8-10 One section of the dual-element microphone couples through the earplug to sample the sound pressure levels in the ear canal, and the other section samples the external sound field. By developing special probed versions of Aearo earplugs, we can now test in a matter of moments the attenuation that is being obtained regardless of the fit of the HPD that is being evaluated. The actual measurement for any one fit in one ear takes about 10 seconds to obtain data at the standard 7 test frequencies from 125 Hz to 8 kHz, as well as an overall noise reduction rating called the Personal Attenuation Rating (PAR). In addition to the brevity of the test, it can be conducted in substantially higher noise levels than can a field REAT measurement.

The PAR, though it appears to be an exact number, also contains its own variability, albeit much less than in the classical approach of using mean laboratory data for individual field predictions. The exact amount of variability in PAR is defined and explicitly provided with the measurement.

The Benefits of Individual Fit Testing

Individual fit testing serves many purposes in a hearing conservation program, but first and foremost it is a tool to train and motivate employees to wear their hearing protectors. A common shortcoming in hearing conservation programs (HCPs) is lack of training; even when training is attempted, lack of ability to demonstrate that the training has accomplished its goals presents a problem.

|

| Figure 1. Components of the F-MIRE. |

With a quick and accurate fit-testing system like F-MIRE (Figure 1), the hearing conservationist has a tool to select the proper hearing protector in terms of fit, and then to work with the employees to make sure they have the knowledge and skill to repeatedly insert the product correctly. In turn this helps motivate the employees since they come to believe in the efficacy of their own behavior (ie, “it is worth the effort to do these things; I can make a difference”).

Not only do the employees need training in the use of their HPDs, but the trainers also need to learn how to train others. This train-the-trainer application is a key feature of the F-MIRE approach. Now trainers can learn what makes a difference and how to direct users to get the most from their hearing protection.

Beyond correct fitting, the hearing conservationist may wish to assign HPDs based on noise exposure levels and/or the need to communicate clearly. In fact, European and Canadian standards (EN 45811 and CSA Z94.2-0212) specifically make such recommendations to match the HPD’s attenuation to a 15 dB wide target protection window. Without the individual fit test data like the F-MIRE can provide, this matching of HPD to noise exposure/communication scenario is a folly. With the reliable octave-band attenuation and PAR that the F-MIRE estimates, such HPD matching is now feasible and reasonable.

When employees experience an OSHA-defined standard threshold shift (STS), one of the follow-up actions is to refit and retrain employees in the use of their HPDs and to provide more protective devices if needed. Now this can be done with a degree of reliability using F-MIRE to determine if in fact employees need this retraining, to assess the protection they can obtain, and whether more is needed. Companies are also concerned if they are meeting OSHA requirements for adequate protection. The regulation directs them to use the labeled NRRs in spite of the unreliability of these ratings. Alternatively, when OSHA compares the relative efficacy of HPDs and hearing conservation, the employer is directed to derate by 50%. Neither approach is accurate. An F-MIRE alternative, though not yet approved by OSHA, is likely to become accepted because of its much greater face validity. (This is an area in which Aearo will be arguing the case at the Federal level.)

Although F-MIRE is ideally intended for individual application, there are times when a company may wish to audit a department or facility. F-MIRE could be applied on a large-scale basis by testing employees in a group and statistically summarizing and reviewing the results. Action could then be taken on an as-needed basis.

A final application of F-MIRE is for documentation for legal purposes. Though not yet tested in court, the concept of documenting training and validating that an employee was able to demonstrate correct and adequate use of a hearing protector would likely be valuable evidence in workers’ compensation proceedings.

Conclusion

For over a quarter-century, since the advent of modern hearing conservation regulations, we have been saddled with the knowledge that many hearing conservation programs are ineffective. Too often this is due to the simple fact that the key component of those programs—the object between the employee and a hazardous noise exposure, namely the hearing protector—is not doing its job. Worn correctly and consistently, HPDs can prevent noise-induced hearing loss in virtually all cases. A significant step in the resolution of this problem is individual fit testing, and F-MIRE now makes that possible. As its use becomes more widespread, it is quite possible that such testing may become the standard for judging effective hearing conservation programs.

Elliott H. Berger, MS, is senior scientist of auditory research at E-A-R/Aearo Technologies and E-A-RCALSM Laboratory, Indianapolis. Correspondence can be addressed to Elliott H. Berger, E-A-R Inc, 7911 Zionsville Road, Indianapolis, IN 46268-1657; (317) 692-3031; e-mail: .

References

- Berger EH. The Naked Truth About NRRs (EARLog #20). Indianapolis: E-A-R Hearing Protection Products; 1993.

- Gauger D, Berger EH. A New Hearing Protector Rating: The Noise Reduction Statistic for Use with A Weighting (NRSA). A report prepared at the request of the U. S. Environmental Protection Agency, reviewed and approved by ANSI S12/WG11; E-A-R 04-01/HP; 2004.

- Berger EH. Assessment of the performance of hearing protectors for hearing conservation purposes. Noise & Vib Control Worldwide. 1984; 15(3):75-81.

- Berger EH. Review and tutorial—Methods of measuring the attenuation of hearing protection devices. J Acoust Soc Am. 1986;79(6), 1655-1687.

- Berger EH. Use of circumaural and supra-aural earphones to measure the real-ear attenuation of earplugs. Paper presented at: American Industrial Hygenic Conference; San Francisco, Calif, Paper 39; 1988.

- Berger EH. Exploring procedures for field testing the fit of earplugs. In: Proceedings of the 1989 Industrial Hearing Conservation Conference. Lexington, Ky: University of Kentucky Office of Engineering Service; 1989:7-10.

- Berger EH. Hearing Protection Devices. In: Berger EH, Royster LH, Royster JD, Driscoll DP, Layne M, eds. The Noise Manual, 5th Edition. Fairfax, Va: American Industrial Hygenic Assoc; 2002: 379-454.

- Voix J, Hager LD, Zeidan J. Experimental validation of the objective measurement of individual earplug field performance. Paper presented at: EuroNoise 2006, Tampere, Finland; 2006.

- Voix J, Laville F. Expandable Earplug with Smart Custom Fitting Capabilities. Paper presented at: InterNoise 2002, Dearborn, Mich; 2002.

- Voix J, Laville F. New Method and Device for Customizing in Situ a Hearing Protector. Canadian Acoustics. 2004;32(3):86-87.

- British Standards Inst (BSI). Hearing Protectors—Recommendations for Selection, Use, Care and Maintenance—Guidance Document (EN 458:1994). London, UK: BSI; 1994.

- Canadian Standards Assn (CSA). Hearing Protection Devices–Performance, Selection, Care, and Use (Z94.2-02). Rexdale, Ont: CSA; 2002.