Moisture and electronics do not make good companions. Damage from moisture is one of the leading reasons for hearing aid repair. So, can hearing aids be truly waterproof and not “just” water-resistant? The answer is yes. Here are the tests,test procedures, and results that prove it.

At one time or another, we’ve all wondered about the effects that water may have on a product that we own. It could be a new watch, a recently purchased smart phone, or those expensive hiking boots. For many people, however, the biggest concern regarding moisture is its effects on one particular product—their hearing aids.

Moisture and electronics do not make good companions. Damage from moisture is one of the leading reasons for hearing aid repair. Common problems are electrical shortages, condensation, and corrosion. Additionally, moisture can clog the air holes of the zinc air battery. This unwanted moisture can be from weather/humidity, the perspiration of the user, or accidental water incidents. Problems associated with moisture in hearing aids can be very frustrating for the patient, as often the hearing aid “dies” unexpectedly, with no quick remedy available.

Over the years, there have been many attempts to solve the hearing aid moisture problems. Devices, such as protective wrappers or sleeves, dehumidifying kits, and special hearing aid dryers, have been introduced. More recently, special nanocoatings have been used that make the hearing aids water-resistant—a significant improvement over hearing aids of previous generations. But is water-resistant good enough?

Water-Resistant vs Waterproof

The words “water-resistant” and “waterproof” seem to be tossed around quite a bit, and sometimes used interchangeably, which is not correct. When something is referred to as water-resistant, it means it can withstand the effects of rain, snow, perspiration, and other general applications of moisture. It does not mean it can be submerged in water. On the other hand, when something is labeled waterproof, it means that the product can withstand total submersion in water.

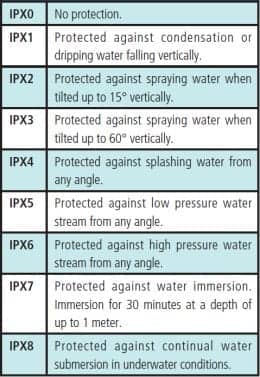

Because this labeling is important, there is an international standard regarding the water-resistant or waterproof qualities of a product (International Standard ANSI/IEC 60529).1 The scale used is the International Protection (IP) rating, also referred to as an Ingress Protection (IP) Rating. Based on documented testing, items are given an “IP” rating, which are the letters “IP” followed by one or two numbers (depending on criteria evaluated; a hearing aid, for example, could be evaluated for both dust and water, which would then be a two-digit suffix). If only one criterion is used (eg, water), then an “X” replaces the other digit. For example, the IP rating scale for water goes from “IPX0” (don’t get this hearing aid close to water) to “IPX8” (this hearing aid is protected against continual water submersion). An IPX rating of “7” or “8” is required for a product to be labeled waterproof. Table 1 summarizes the different IPX ratings for water exposure.

TABLE 1. IPX ratings for water exposure (International Standard ANSI/IEC 60529).1

Designing a “Waterproof” Hearing Aid

There are two major challenges that complicate the construction of a waterproof hearing aid:

- As the name suggests, air-conducted sound needs air to travel, which is a problem if the hearing aid is completely sealed;

- Hearing aid batteries (zinc air) need air to operate.

The most straightforward way to make hearing aids waterproof would be to completely seal the instruments. However, this would sacrifice the basic functionalities: microphones and receivers would not work, and the battery would not provide any power. No sound at all! Thus, the key to design a waterproof hearing aid is to find ways to keep water out, but let air in.

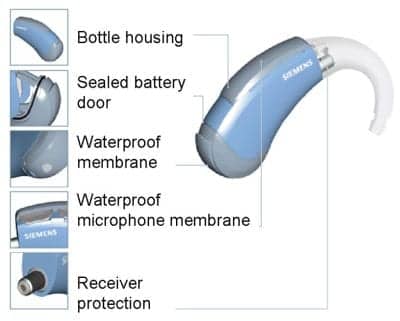

The new Aquaris from Siemens achieves the goal of “waterproof,” and a high level of functionality, by applying five innovations in housing design (Figure 1):

- Bottle housing

- Sealed battery door

- Waterproof membrane in battery door

- Waterproof microphone membrane

- Nanocoated receiver protection

Bottle housing. The housing itself is made of one solid piece, without any screws or seams. Thus, there are no openings where water or dust could enter—like a bottle. Therefore, this approach is referred to as “bottle housing.” Such housing requires a much more complicated manufacturing process than standard BTE housings. Conveniently, however, as the electronic module sits inside the housing like a “message in the bottle,” it is possible to easily exchange the housing.

Sealed battery door. A special battery door seals the housing like one would cork a bottle. A silicon sealing avoids edges at the battery door and therefore prevents water from being drawn into the battery compartment (no capillary effect). The special plastic used in the construction of the battery door perfectly conjoins with the silicon and thus forms a very robust bond. This special battery door design also ensures the contact pressure required to hold back water even during swimming or showering.

Figure 1. Illustration of five innovations to construct a properly functioning waterproof hearing aid.

Battery function. As mentioned, an important design consideration is providing an environment for effective battery operation. This problem was solved by using a waterproof, but breathable, membrane at the bottom of the casing that allows air to pass through to ensure reliable operation with zinc-air batteries.

Microphone membrane. Water protection for hearing aid microphones on conventional hearing aids is at best, “splash water resistant” (eg, IPX4) and therefore could never resist water when the patient is taking a shower or a swim. For Aquaris, a special waterproof microphone protection membrane is used. Similar to the functioning of the eardrum, it is impervious to water, but yet still sensitive to sound waves.

This ultrathin protection membrane sits on a frame above the microphone. This makes it especially vulnerable to hair of the user touching the membrane, which would produce unwanted sounds. Direct physical contact also could potentially damage it. Therefore, this sensitive membrane is protected by a special protection clip, which also protects the microphone from wind that might cause disturbing noise.

Nanocoating for receiver. At the receiver adapter, a gasket seals the connection between the housing and the electronic module. A nanocoated grid protects the receiver and prevents water from entering. In combination with an ear hook and appropriate earmold, the receiver is protected from water even during a swim.

Laboratory Studies of Verification

It was important for this new product to be rigorously evaluated according to International Standard ANSI/IEC 60529.1 The robustness of the Aquaris hearing instrument was tested regarding the effects of dust and water by the independent research laboratory LGA, part of TÜV, Rheinland, Germany. TÜV Rheinland is a well-known global provider of technical, safety, and certification services, with offices in 42 countries. The tests included the IPX5 (dust-proof), IPX4 (splash-proof), and IPX7 (waterproof) tests.

IPX5 dust-proof test. The instrument was subjected to 2 kg (4.4 lbs) of talcum powder (particle size of 75 µm) for a duration of 8 hours. The criteria for “pass” were successful power on after test and subsequent electroacoustic performance meeting standard operational specifications. Result: Pass.

IPX4 splash-proof test. The LGA labs subjected the Aquaris to high pressure water from a fixture that rotated 360° around the instrument (Figure 2) for a duration of 10 minutes. The criteria for passing the test were power on after the test, electroacoustic performance meeting standard operational specifications, and no water inside the housing (based on LGA inspection using bottling paper). Result: Pass.

IPX7 waterproof test. The final test for Aquaris was to subject it to complete submersion in water 1 meter deep for a duration of 30 minutes (Figure 3). The criteria for passing were power on after the test, electroacoustic performance meeting standard operational specifications, and no water inside the housing (based on LGA test engineer inspection). Result: Pass.

As shown in Table 1, according to the water-resistant or waterproof qualities of a product (International Standard ANSI/IEC 60529), passing this test confers an IPX7 rating, which permits the labeling of “waterproof.” To our knowledge, Aquaris is the first and only—as of today—commercially available hearing aid with an IPX7 rating.

Figure 2. Test setup for IPX4 splash-proof test for an 8-hour duration.

Figure 3. Test setup for IPX7, total submersion in water 1 meter deep for a duration of 30 minutes.

Summary

Based on the testing of internationally recognized certification laboratories, Aquaris has been shown to be not only water-resistant, but waterproof. This is achieved as a result of several unique innovations detailed in this article.

The LGA IP testing resulted in a rating of IP57, which means that Aquaris is dust-proof and waterproof. These findings, of course, relate directly to patient benefit and satisfaction. The IP testing (complete submersion) was considerably more rigorous that what would be expected in daily hearing aid use. Our field studies have confirmed that, even in use in extreme conditions of humidity over several months, no failures have been observed (in fact, the field test in Queensland, Australia, from December 2010 to February 2011 included some of the strongest floods and cyclones, or yasi, in Australia’s history). Field study participants also continued to wear the Aquaris during showering and swimming with no failures reported.

As stated in the introduction, moisture and electronics do not make good companions. With Aquaris, however, we have significantly improved the relationship between these two natural enemies.

Reference

- American National Standards Institute/International Electrotechnical Commission. ANSI/IEC 60529-2004: “Degrees of Protection Provided by Enclosures (IP Code).” Rosslyn, Va: National Electrical Manufacturers Assn; 2004.

Citation for this article:

Chalupper J., Flores A. Beneath the Surface: Understanding the Terms “Water Resistant” and “Waterproof” Hearing Review. 2011;18(11): 56-61.