Oxfordshire, United Kingdom — P2i, makers of Aridion, a liquid repellent nano-coating, has announced that the technology is now providing protection against corrosion damage for more than two million hearing aid users worldwide.

Licensed by three of the largest hearing aid manufacturers, Aridion is transforming conventional levels of reliability by substantially reducing warranty failure and repair costs and ultimately increasing user confidence, says the company.

P2i also announced that it will soon unveil details of new compact Aridion processing machines, designed specifically to address the needs of smaller hearing aid manufacturers and dispensers.

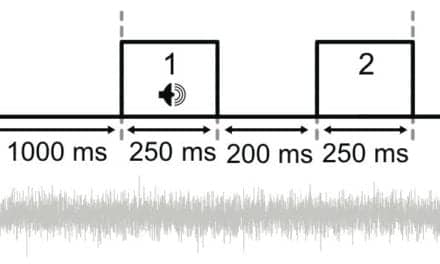

Aridion is applied using a special pulsed ionized gas (plasma), which is created within a vacuum chamber, to attach a nanoscopic polymer layer — a thousand times thinner than a human hair — to the hearing aid. The company reports that this process dramatically lowers the product’s surface energy, so that when humidity or sweat come into contact with it, they form beads and simply roll off.

In addition, since Aridion is designed to coat every aspect of a finished product at the nanoscopic level, it reportedly protects more thoroughly than alternative approaches where individual product components are treated prior to assembly.

SOURCE: P2i