When my long-time friend and HR editorial board member Wayne Staab, PhD, approached me about publishing an article on an “earmold” that is akin to an inflatable balloon, I wasn’t quite sure if he was serious at first. But then there was that smack-your-forehead moment: a small balloon/bubble might easily and effectively seal most canals, be comfortable, and provide open fittings with resonance possibilities (see this month’s feature article “A Voice-activated, Inflatable, Self-regulating Balloon Ear Coupler“). Hmmm… Of course, it should be emphasized that this is an emerging technology and the efficacy of a self-regulating balloon-type ear coupler is still something being developed and investigated. However, if anything, it’s a very interesting and creative approach to overcoming the requirement of fabricating hard acrylic custom earmold shells via the impression-taking process—which more often resembles alchemy or a black art than a science. HR has run enough articles on impression-taking (thank you, Chester Pirzanski et al) during the past two decades to fill several editions.

Certainly, great strides have been made in impression materials and impression-taking techniques, as well as the use of scanners that capture 3D images of impressions. We’ve also gained a lot more insight into how the ear canal changes with jaw movements (eg, see Oliveira et al’s article, “The Dynamic Ear Canal and Its Implications” in the February 2005 HR). On the manufacturing side, the majority of ITE-type earmolds are now being digitally rendered via CAD/CAM technology (see Cortez et al’s article in the March 2004 HR).

In another project, Lantos Technologies (www.lantostechnologies.com) is working to commercialize a 3D digital scanner/probe capable of measuring ear canal shape and tissue compliance. The goal is to eliminate the uncertainties associated with manual fits, thereby improving the performance of custom-made ear products, including hearing aid earmolds, ear and swimplugs, MP3 earphones, etc. The Lantos scanner is said to provide both direct digitization and accurate 3D image information to hearing aid manufacturers for enhanced performance and comfort.

To the layperson, these might seem like small changes. But it’s hard to tell how these types of technologies could influence hearing care. Could a true instant-fit custom earmold change the market in the same way that instant/open-fit slim-tube mini-BTEs and RICs did? With the multifaceted applications of instant-fit custom ITE earmold technology (eg, for MP3 players and cellphone headsets), would having these in-office capabilities open new markets and provide inroads into younger user groups?

-

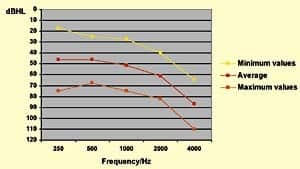

V & V as a gold standard in hearing care. And speaking of small changes producing huge opportunities, this month’s cover story by Better Hearing Institute Executive Director Sergei Kochkin, PhD, on verification and validation (V & V) is an eye-popper. It shows that, if the entire industry utilized V & V, it would obviate the need for 521,779 patient visits—or 391,334 hours of clinical time—for refittings. Referring to Table 7 in this month’s dispenser survey from Phonak Market Research, at an average professional rate of $144 per hour, this translates into more than $56.3 million in gross revenues. HR has run many articles on the value of real-ear measurement and validation. For example, Aarts and Caffee (November 2005 HR) showed that less than 12% of predicted REAR values in first-fit software were clinically similar to real-ear values. More recently, an April 2011 HR article by Stender et al showed how it’s possible (and advantageous) to implement V & V in a busy dispensing practice. The argument for making V & V a gold standard in hearing care was already extremely persuasive; when tied to convenience and cost savings for consumers and dispensing practices alike, it places on exclamation point on the need for implementing V & V.

-

Understanding and benchmarking your practice. As demonstrated with V & V, small changes in a practice can lead to big things. The dispenser survey compiled by Phonak Market Research is an extremely useful glimpse into factors such as gross revenues, staffing, and revenue per staff member. By using the survey and its companion online worksheet, Practice Performance Comparisons (PDF), you can benchmark your hearing care business against those of similar sizes and types. In doing so, you may find some small things that lead to big changes in your practice.

Karl Strom

Editor-In-Chief